Joey is an unbiased footwear designer and founding father of Khamis Studio based mostly in Indianapolis. He has designed for iconic manufacturers and artists resembling Kanye West, Columbia SW, and Reebok. After graduating from Purdue College he acquired his begin within the footwear business designing footwear for Columbia Sportswear and Reebok, the place he designed the Cardi B Traditional Leather-based. As a designer, he focuses on consistently exploring new mediums of creation to provide you with modern designs, processes, and options to the issues he is fixing.

The primary pattern obtained precisely mirrored the design intent, and matched what would usually be anticipated after an additional two rounds of revisions. By slicing out 2D blueprints and collaborating instantly in 3D with the manufacturing unit, solely minor tweaks had been left to make earlier than giving the approval for manufacturing.

“we’re designing 3D merchandise, so it is smart to be exploring concepts in a 3D house”

Compensate for Joey’s 2023 Round session on the Intuition workflow and advantages

Hear Joey and the Gravity Sketch workforce the beginning of the Khamis Studio x Gravity Sketch challenge

adidas: designing efficiency merchandise in 3D

adidas shares how they cut back product creation time utilizing 3D instruments.

COMPANIES THAT USE GRAVITY SKETCH EVERYDAY

Gravity Sketch is an intuitive 3D design platform for cross-disciplinary groups to create, collaborate, and evaluation in a wholly new manner.

© 2024 Gravity Sketch. All rights reserved

Product design innovation in motion: The Khamis Studio x Gravity Sketch shoe took on a 3D-first method to problem the normal processes used to carry footwear to life

3D isn’t simply the product of a single software or function, it’s a way to speak concepts, in a language all of us perceive. And to construct the absolute best product, it’s essential to talk concepts throughout the whole workflow, not simply on the finish.

Embracing the most recent instruments and shifting in the direction of a 3D-first workflow can treatment obstacles ingrained in typical, extra conventional, approaches. By leveraging Gravity Sketch from the early levels of design and ideation, via to manufacturing, you’ll be able to reduce rounds of sampling, facilitate a streamlined and environment friendly improvement course of, with higher communication of the design intent.

The Khamis Studio x Gravity Sketch Intuition shoe was born from the need to ship a product that remained true to the design intent from the concept to manufacturing; this can be a feat that’s extremely difficult however one thing business strives to do all through the product course of. At Gravity Sketch, we’re lucky to see the unimaginable work from our most progressive prospects, however are unable to share plenty of this with the world, but! Partnering with Joey Khamis of Khamis Studio to doc an end-to-end footwear design and improvement course of provides the group the chance to see a tangible instance of a future-forward footwear design workflow, and its advantages. All through the method Joey has leveraged a number of of the identical instruments and applied sciences we’ve been seeing the business transfer in the direction of.

Analysis and Inspiration

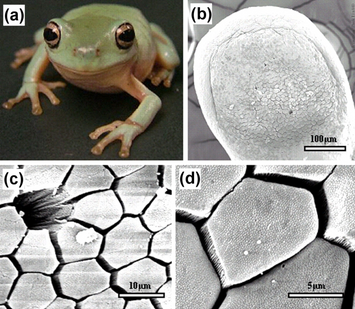

The inspiration for the Khamis / GS shoe was taken from nature, a typical supply of concepts and references for work coming from Khamis Studio.

For Joey’s design he seemed on the dart frog: the textures current of their ft impressed the texturing of the outsole and tooling.

One other supply of inspiration is from cacti – that when dehydrated shrivel as much as create a protecting barrier. This protecting barrier appears delicate to the attention however is shielding the plant. Joey needed this texture and protecting properties mirrored in his design.

Joey introduced all of his inspiration photos right into a digital studio and shared it with the Gravity Sketch founders in an immersive VR presentation, which helped promote the preliminary design route and construct conviction within the method.

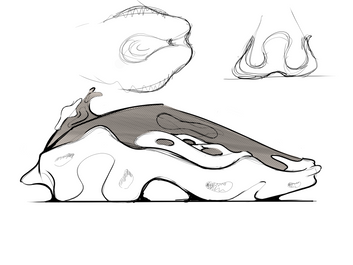

Sketching and Ideation

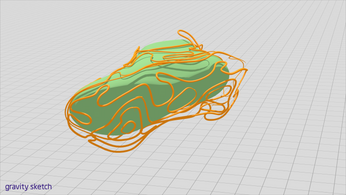

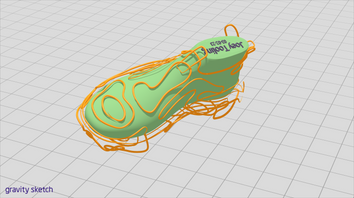

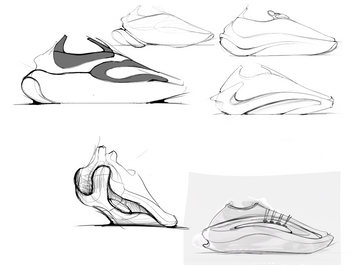

The sketching and ideation part within the footwear design workflow started in Procreate with some fast serviette sketches that might be introduced into Gravity Sketch as references. These together with inspiration photos, gave Joey the idea to start out exploring concepts, and developing foundational wireframes round a final, additionally imported into Gravity Sketch. 3D wireframing gave Joey the chance to discover and share extra tangible choices that mirrored his intent a lot earlier within the course of

The main target then shifted in the direction of defining the primary strains of the shoe and establishing the silhouette, with 3D splines that might be used later for geometry focus. There was explicit consideration paid to the location of the final to make sure the work would meet the manufacturing constraints. This method allowed for the swift decision of design challenges and a deep understanding of proportions, which accelerated the workflow in comparison with conventional strategies.

By addressing key components early within the course of, the workforce gained a fast understanding of the design’s feasibility and aesthetics, streamlining the transition to 3D surfacing.

Assessment and Suggestions

Members of the Gravity Sketch workforce and Joey had been situated in several geographies, however might be introduced into the digital studio atmosphere utilizing VR or the Gravity Sketch desktop app to expertise Joey’s concepts, ideas, and designs collectively. This enabled all stakeholders to get on board with actual and significant collaboration happening. By way of utilizing this type of communication the workforce understood the proposal holistically and had been in a position to concentrate on securing the route of the ultimate design.

The earliest evaluation session for the design route showcased inspiration and 4 major 3D ideas created by Joey. Quite a few fashions and designs had been offered, adopted by an energetic dialogue surrounding workflow, aesthetics, and supplies, in addition to discussing the following steps for the challenge.

Iteration and refinement

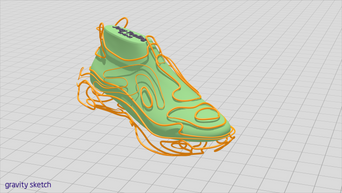

Within the iteration and refinement part of the workflow, the exploration of form began with surfacing. Persevering with to depart from conventional sketches, Joey opted for a 3D modeling method to completely notice designs, enabling extra knowledgeable and exact decision-making throughout preliminary critiques.

As the method unfolded, the aesthetic seamlessly aligned with a singular design route, integrating performance from a various array of ideas.

Presentation and hand-off

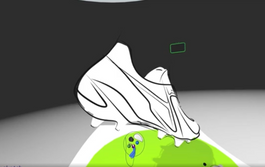

The presentation and handoff levels within the Intuition design workflow used highly effective rendering instruments like Blender, and KeyShot to provide lifelike representations of the product so the workforce to see what the shoe would seem like with manufacturing supplies. These renders, based mostly on knowledge exported from Gravity Sketch, not solely offered visualizations, but additionally served as a basis for refining texture and colorway ideas. The objective was to attain a stage of realism that allowed for probably the most correct decision-making doable for the aesthetics of the shoe.

Joey exceeded expectations by having 4 ideas able to evaluation, constructed on from the preliminary early Procreate sketches and 3D wireframes. The element captured in these idea designs confirmed the expressive intent of the envisioned product far earlier within the course of than was anticipated. Fast volumetric types conveyed components resembling laces and padding, contributing to the communication and understanding of how Joey was approaching the design and its building.

Every participant was in a position to independently transfer across the work to discover areas and particulars of designs that the majority associated to their self-discipline. These reviewers had been ready to make use of instruments inside Gravity Sketch to focus on areas of the shoe to raised illustrate factors of dialog, in addition to discover the ideas in nice element; at scale and even zoomed in for a greater understanding of the main points.

This evaluation session ensured alignment for everybody concerned and gave them a possibility to ask questions and higher perceive Joey’s method in a dynamic and interesting arrange.

A digital tech pack, constructed and viewable inside Gravity Sketch, performed a pivotal function within the transition to the event part. The mannequin underwent an iterative course of for creating its 3D tech pack: The weird technique of sharing 3D recordsdata relatively than simply conventional 2D blueprints, resulted in additional insightful suggestions. There was a constructive reception to the succinct 2D tech pack, comprising solely three pages for tooling and higher sections, with UV unwrapping for the higher derived instantly from the 3D mannequin.

The refinement course of additional unfolded in digital actuality (VR), as suggestions and edits flowed between Joey and the manufacturing unit. The strategy of reviewing designs in VR allowed for detailed, mm-level changes to be made collaboratively because the workforce may zoom in to deal with issues which may elude seize via blueprints or the 3D recordsdata alone. This complete method ensured that the ultimate particulars carefully aligned with Joey’s design intent.

The ensuing footwear design is characterised by its slip-on nature, designed for intuitive and easy put on: Strategic zones of padding had been integrated to boost visible consolation and supply safety for each the highest of the foot and across the ankle.

A notable characteristic of the shoe’s design emerged with a 2-in-1 moulded heel counter, serving as a touchpoint interplay that Joey created to replicate Gravity Sketch’s distinctive consumer expertise. The heel tab, designed to supply each assist and exterior reinforcement, types a particular construction that extends into twin heel tabs, merging seamlessly with the higher. This design not solely enhances performance but additionally introduces an modern option to open the shoe from the heel, showcasing the iterative refinement and considerate consideration that outlined this part of the design course of.

Communication with the manufacturing unit

It was transformational to see such a deep stage of collaboration with the manufacturing unit accomplice at a comparatively early stage of the method. The manufacturing unit obtained each Rhino and Gravity Sketch recordsdata, to discover the design’s geometry. The manufacturing unit didn’t have plenty of background information on how the Sub-D knowledge generated by Gravity Sketch associated to Rhino, so the workforce made a brief video displaying how it may be used to edit and manipulate the mannequin shortly to ship concepts and revisions again to Joey.

Supercharged collaboration

Speaking in a digital studio, throughout geos, and decreased friction factors, unlocking a transformative distant workflow with the manufacturing unit accomplice

Clear communication in 3D saved a full pattern spherical, lowering journey prices and environmental impression. Saving 3 months in improvement time

Get Began with Gravity Sketch →

Joey was in a position to discover concepts and a number of ideas 2-3x sooner than he usually would earlier than refining the design route

By way of implementing this workflow the workforce realised three key efficiencies in comparison with a conventional course of:

Joey and the Gravity Sketch workforce opted for a 3D tooling file over a conventional 2D blueprint to treatment the minor modifications wanted. This swap enabled collaborative evaluation inside Gravity Sketch, empowering them to supply knowledgeable and exact feedback and choices. These feedback knowledgeable changes made inside the 3D file. The file was seamlessly exchanged between manufacturing unit companions utilizing Rhino, minimizing the necessity for quite a few back-and-forth hand-offs between the Gravity Sketch workforce and the factories.

Weeks to months of time is generally what it takes to go from tech pack to this stage of a pattern.

Discover in 3D

Entry a folder of belongings associated to the shoe, together with early iterations, in addition to extra refined floor fashions, lasts and tooling. At no cost!

Go to Khamis Studio Property →

Contents

The communication of a product via orthographic views leaves lots to the creativeness. Usually miscommunication results in further work, bodily sampling, and interpersonal frustrations. 3D has the power to strengthen the connection between all stakeholders engaged on the challenge.

Ideation classically takes place with pen on paper, it’s quick and helps unlock concepts for the designer; it is a true artwork type that we love. Nonetheless, ideating across the true physicality of the concept and capturing volumetric data and contractions of the work can’t be completed with 2D mediums.

|

Most footwear require quite a few pattern iterations to precisely replicate the designer’s intent.These a number of rounds of sampling results in a necessity for designers to fly to the manufacturing unit and work hand in hand with the companions to lock within the ultimate product. |

Discover in 3D

Entry a folder of belongings associated to the shoe, together with early iterations, in addition to extra refined floor fashions, lasts and tooling. At no cost!

Go to Khamis Studio Property →